Table of Contents

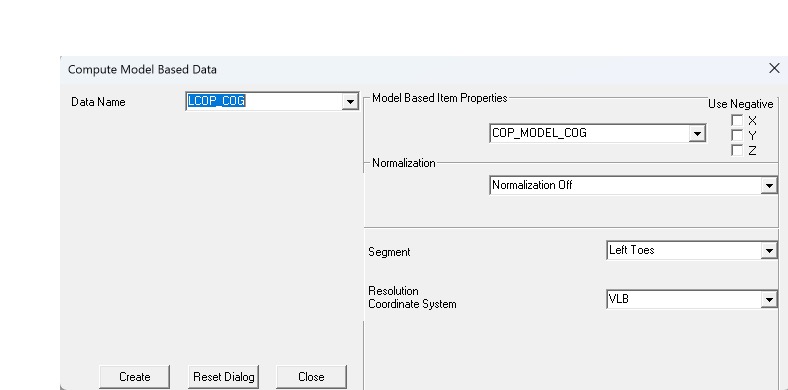

COP MODEL COG

Creating a LINK_MODEL_BASED signal called the COP_MODEL_COG is a more general way to compute the difference between the center of pressure and the projection of the MODEL COG.. The command checks all force assignments to the specified segment and any force platform. The signal is then transformed (or resolved) into the specified local coordinate system). All occurrences (eg. all force platforms) are included to determine if the segment has been assigned to the force signal.

By default, normalization is by segment length.

Model Based Item

Pipeline Command

Compute_Model_Based_Data /RESULT_NAME=LCOP_COG /FUNCTION=COP_MODEL_COG /SEGMENT=LTO /REFERENCE_SEGMENT= /RESOLUTION_COORDINATE_SYSTEM=VLB /USE_CARDAN_SEQUENCE=FALSE /NORMALIZATION=FALSE /NORMALIZATION_METHOD=DEFAULT_NORMALIZATION /NORMALIZATION_METRIC= ! /NEGATEX=FALSE ! /NEGATEY=FALSE ! /NEGATEZ=FALSE ! /AXIS1=X /AXIS2=Y ! /AXIS3=Z ;

Resolution Coordinate System

The coordinate system used by the model based items is precisely the coordinate system you see in the animation viewer. The length of the segment is defined from the proximal end to the distal end of the segment regardless of what axis you call this, and the proximal and distal radius are defined by the segment definition.

Sign Convention

In order to get the signs of the COP_MODEL_COG to be consistent between the left and right leg (e.g. how to get around the fact that Visual3D enforces the right hand rule), you can select the check boxes in the dialog to negate one or more components.

Normalization

The default normalization is relative to length (distance between proximal and distal ends of the segment) of the segment that is assigned to the force vector.

A negative axial value means the COP is behind the COG and a positive axial value means the COP is in front of the COG.