Table of Contents

RT Plugin Bertec AM6X01

Overview

The Bertec AM6X00™ Plugin is used in Visual3D Server™, and Visual3D RT™, it connects to Bertec™ hardware.

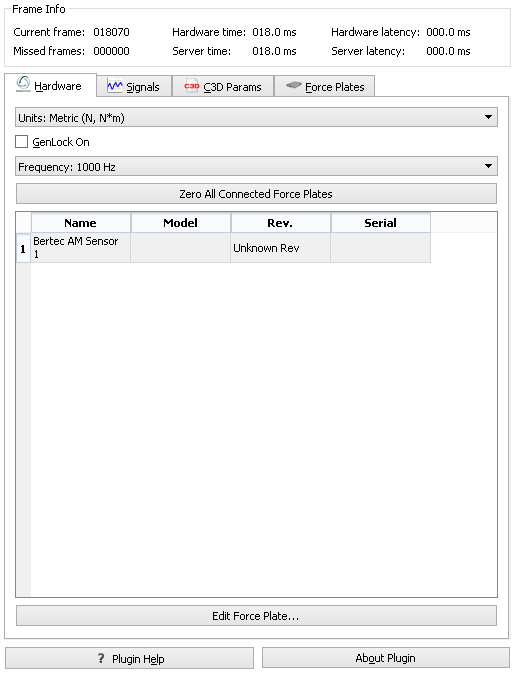

Plugin Interface

The “Plugin Help” button leads to this web page should you need to reference this page in the future.

The “About Plugin” button has details on the plugin being used including version, release date, copy right, support contact information and the hardware SDK version.

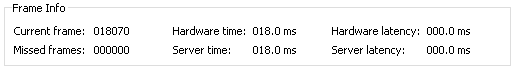

Frame Info

Current frame The current frame number on the top left hand side on the screen (where it currently reads 018070) keeps a count of the current frame which is assigned by the hardware or software system.

Missed frames The missed frames number is on the bottom left (where it currently reads 000000). Whenever there is a gap in frames sent by the hardware of software system a blank frame is inserted. The dropped frames count keeps a record of both the number of frames which are blank.

Hardware time The hardware time number is on the top, in the centre (where it currently reads 018.0 ms). This time stamp is created by the hardware being used and is how long, in milliseconds, the hardware has been running.

Server time The server time number is on the bottom, in the centre (where it currently reads 018.0 ms). This time stamp is created by the server and is how long, in milliseconds, it has been connected to the hardware or software which is streaming to it.

Hardware latency The hardware latency is on the top right hand side (where it currently reads 000.0 ms). This indicated the delay created by the hardware system.

Server latency The hardware latency is on the top right hand side (where it currently reads 000.0 ms). This indicates any delay introduced by the server.

Hardware

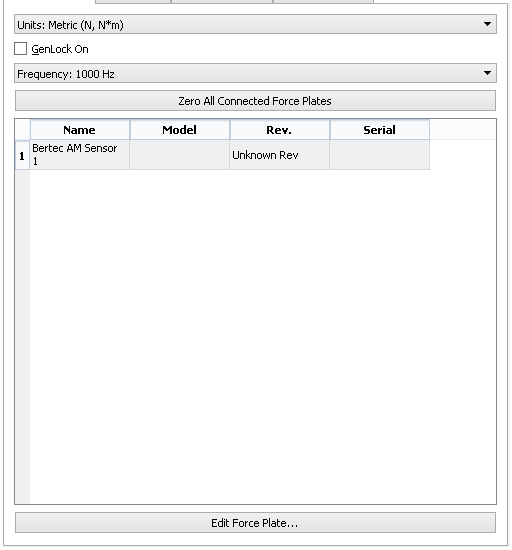

Units

The Units setting are only available in Metric and may either be set to Unconditioned or Conditioned. Unconditioned allows the signal conditioner to act as a traditional analog amplifier. Conditioned uses the signal conditioner to invert the sensitivity matrix to eliminate cross-talk. It also allows the signal conditioner to correct for channel excitations, channel gains, cable length, and bridge resistances.

Genlock

Genlock may be set to OFF (unchecked), or ON (checked). Genlock is used only when there are more than one system in use (i.e. the force platforms and a camera system). It allows the systems to be synchronized and is set on the back of the force platform amplifier. The Genlock works by sending regular electrical pulses to the computer. Setting Genlock to off will tell the computer to ignore these pulses. Setting the Genlock to on means that the computer will acknowledge the pulse.

Frequency

While force platforms generated an analogue signal it is necessary to convert the analogue data into digital frames in order to process it and in order to use it along side digital data, such as what is generated by a camera system. In order to divide the analogue signal into frames of data you must specify the rate at which you would like to sample the data. The frequency for sampling is measured in Hertz, where 100 Hz is 100 frames per second. At the moment the only frequency setting allowed by the Bertec Force Platforms is 1000 Hz.

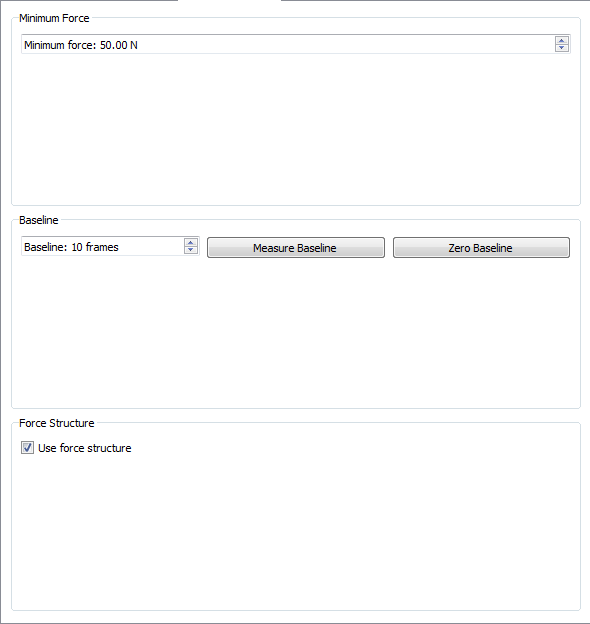

Zero All Connected Force Plates

When the Zero Force Plate button is used it will reinitialize the force platform hardware by resetting the channels to their lowest level. This allows you to define a level of zero force, which is useful if there is something covering the force platform.

Hardware Specifications Table

The Hardware Specifications Table has a list of the hardware units that are connected to Visual3DServer. Not all hardware systems will populates all four columns as not all manufacturers number in four distinct ways on their hardware. The first column “Name” has the make of the hardware (AMTIGen5 for example) and the number of the hardware piece, in case there are more than one type of the same make and model (1, 2, 3 . . .). The second column “Model” lists the hardware model number. The third column “Rev.” lists the hardware Revision number which is used by certain hardware system manufacturers and is specific to the piece of hardware. The fourth column “Serial” lists the serial numbers of the hardware pieces which are connected.

Edit Force Plate

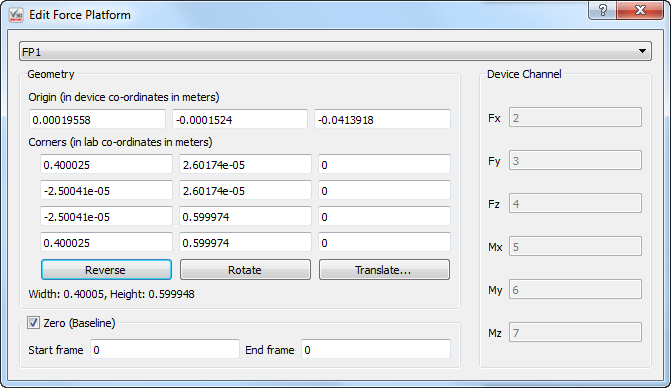

The Edit Force Plate button will open the Edit Force Plate Window as seen to the right.

At the top of the window is a drop down menu which allows you to select which force platform you would like to make changes to. In the sample picture it is set to FP1.

To the far right of the window is the Device Channel list. This cannot be adjusted but provides a readout of channels which are being used by the force platform

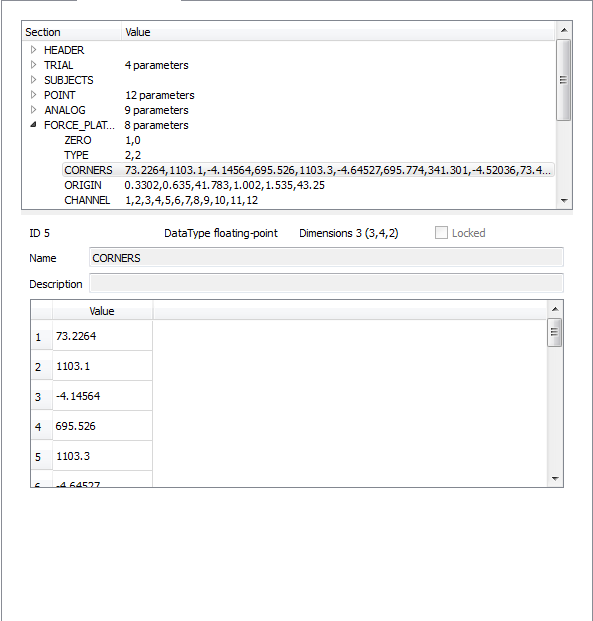

The Geometry section of the window includes the Origin, the Corners, and the Width and Height. The Origin indicates where the Origin (0,0,0) is located relative to the force platform's co-ordinate system. Values are in meters and can be altered by the user. The Corners are the co-ordinates of the each of the force platform's corners relative to the lab co-ordinate system. Values are measured in meters and can be altered by the user. There are three buttons associated with the Corners section which allow the user to easily manipulate where the force platform is located in the lab co-ordinate system. The Reverse button allows the user to change the numbering of the force platform corners making the numbering go counter clockwise if it is initially set at clockwise. This has the result of changing which direction the force platform decides is up. The Rotate button allows the user to twist the force platform in place in increments of 90 degrees. The Translate button allows the user to move the force platform along any of the three axis (x, y, and z) by the magnitude that is entered. The Width and Height is provided to the computer by the Visual3DServer by the force platform and it can be changed by the user if they change the locations of the corner co-ordinates to describe a force platform with different dimensions.

Signals

C3D Params

Force Platform

3D View

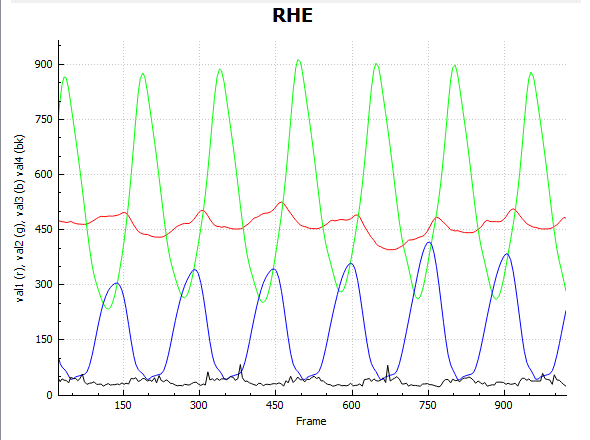

The right hand side of the screen provides a real-time 3D graphical representation of the data being streamed.

Save 3D View

This button allows you to save what is currently being displayed in the 3D view graphics area. The image can be saved in a number of standard formats, such as .bmp, .ico, .jpeg, .jpg, .pbm, .pgm, .png, .ppm, .tif, .tiff, .wbmp, .xbm, or .xpm. This function is ideal for producing graphics for papers or presentations. Saved images can be edited with 3rd party graphics programs if needed.

Copy 3D View to clipboard

This button allows you to copy what is currently being displayed in the 3D view graphics area to the clipboard. This allows you to paste the image into any program that supports copy and paste. This is useful for working with presentation or graphics editing software.

Reset camera 3D View

This button brings the 3D viewer back to it's beginning position. You may find that having used the rotation, translation, and zooming capabilities of the 3D view you have lost track of where you are in the graphics, which can make returning to a proper view of your data challenging. The reset view button removes this frustration and reorients you.

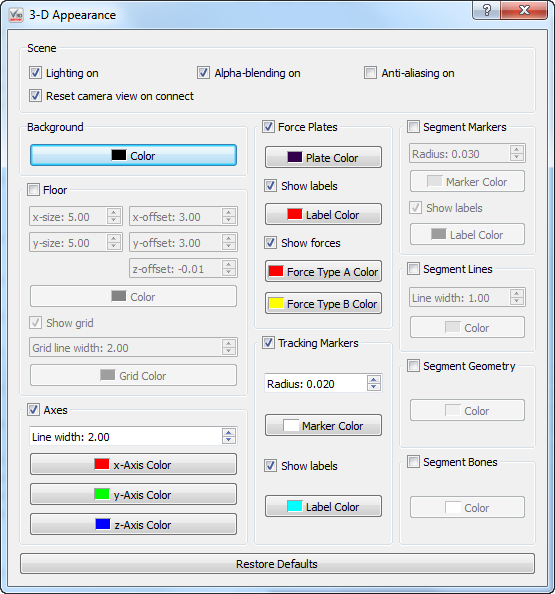

3D View Preferences

This button allows you to change how the graphics that are presented to you. Changes happen in real time. At the bottom is the “Restore Defaults” button which resets all of the options to their standard setting.

= Scene =

Lighting on - When selected graphics that are suppose to be 3 dimensional have shadows to help simulate shape. When not selected objects are one solid color.

Reset camera view on connect - When this box is selected and you connect or reconnect to hardware the camera view will reset to it's default.

Alpha-blending on - When this box is selected the graphics are slightly transparent and allow you to see what is behind them

Anti-ailiasing on - When this box is selected all the lines in the graphics are smooth. If it is not selected the lines that are not either horizontal or vertical change directions portion by portion.

= Background =

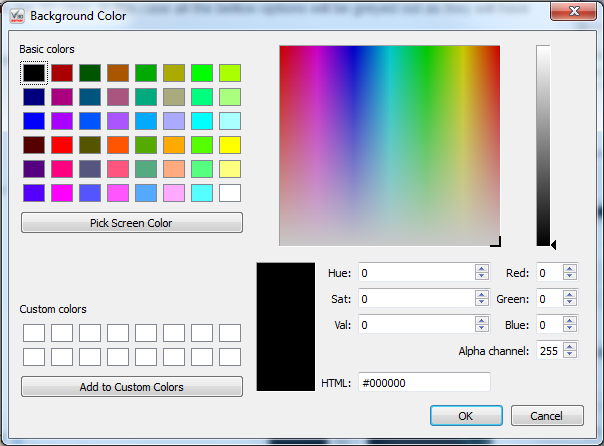

Color - This allows you to change the background color to anyone you chose.

= Floor =

When the check box next to the floor is not checked the floor will not appear in the 3D View. In this case all the bellow options will be greyed out as they will have no effect if the floor is not present.

X-size - This allows you to customize how many panels the floor is composed of in the x direction. the minimum is 1 and maximum is 100. The default size is 5.00.

Y-size - This allows you to customize how many panels the floor is composed of in the y direction. the minimum is 1 and maximum is 100. The default size is 5.00.

X-offset - This allows you to shift the entire floor along the x-axis either in the positive or negative direction. The maximum value allowed is 100 and the minimum value is -100. The default setting is 3.00.

Y-offset - This allows you to shift the entire floor along the y-axis either in the positive or negative direction. The maximum value allowed is 100 and the minimum value is -100. The default setting is 3.00.

Z-offset - This allows you to shift the entire floor along the z-axis either in the positive or negative direction. The maximum value allowed is 100 and the minimum value is -100. The default setting is -0.01.

Color - This allows you to change the floor color to anyone you chose.

Show grid - This allows you to remove the grid lines from the floor by unchecking the checkbox.

Grid line width - This allows you to change the thickness of the gridlines. The minimum value is 1 and the maximum value is 10. The default width is 2.00.

Grid color - This allows you to change the grid line color to anyone you chose.

= Axes =

When the check box next to the axis is not checked the axis will not appear in the 3D View. In this case all the bellow options will be greyed out as they will have no effect if the axis is not present.

Line width - This allows you to change the thickness of the axis lines. The minimum value is 1 and the maximum value is 10. The default value is 2.00.

X-Axis Color - This allows you to change the x-axis line color to anyone you chose.

Y-Axis Color - This allows you to change the y-axis line color to anyone you chose.

Z-Axis Color - This allows you to change the z-axis line color to anyone you chose.

= Force Plates =

When the check box next to the force plates is not checked the force plates will not appear in the 3D View. In this case all the bellow options will be greyed out as they will have no effect if the force plates are not present.

Plate Color - This allows you to change the force plate color to anyone you chose.

Show labels - This allows you to remove the force plate label, (such as FP1, FP2 . . . etc) from the 3D view.

Label Color - This allows you to change the force plate label color to anyone you chose.

Show forces - When checked the forces will be show in the 3D view using arrows.

Force Type A Color - This allows you to change the color of the raw force arrows to anyone you chose.

Force Type B Color - This allows you to change the color of the force structure arrows to anyone you chose.

= Tracking Markers =

When the check box next to the tracking markers is not checked the tracking markers will not appear in the 3D View. In this case all the bellow options will be greyed out as they will have no effect if the tracking markers are not present.

Radius - This allows you to change the radius of the markers. The maximum value is 0.100 the minimum value is 0.001. The default radius is 0.020.

Marker Color - This allows you to change the color of the marker color to anyone you chose.

Show Labels - This allows you to remove the marker labels from the 3D view.

Label Color - This allows you to change the color of the label to anyone you chose.

= Segment Markers =

When the check box next to the segment markers is not checked the segment markers will not appear in the 3D View. In this case all the bellow options will be greyed out as they will have no effect if the segment markers are not present.

Radius - This allows you to change the radius of the markers. The maximum value is 0.100 the minimum value is 0.001. The default radius is 0.020.

Marker Color - This allows you to change the color of the marker color to anyone you chose.

Show Labels - This allows you to remove the marker labels from the 3D view.

Label Color - This allows you to change the color of the label to anyone you chose.

= Segment Lines =

When the check box next to the segment lines is not checked the segment lines will not appear in the 3D View. In this case all the bellow options will be greyed out as they will have no effect if the segment lines are not present.

Line Width - This allows you to change the thickness of the segment lines. The minimum value is 1 and the maximum value is 10. The default value is 1.00.

Color - This allows you to change the color of the segment lines to anyone you chose.

= Segment Geometry =

When the check box next to the segment geometry is not checked the segment geometry will not appear in the 3D View. In this case all the bellow options will be greyed out as they will have no effect if the segment geometry is not present.

Color - This allows you to change the color of the segment geometry to anyone you chose.

= Segment Bones =

When the check box next to the segment bones is not checked the segment bones will not appear in the 3D View. In this case all the bellow options will be greyed out as they will have no effect if the segment bones are not present.

Color - This allows you to change the color of the segment bones to anyone you chose.